When it comes to boiler maintenance, two common challenges that arise are scale and sludge buildup. Both scale and sludge can significantly impact the performance and efficiency of a boiler system, leading to increased energy consumption, reduced heat transfer efficiency, and potential equipment failure. In this comprehensive guide, we will delve into the differences between scale and sludge, exploring their formation, composition, effects on boilers, removal methods, and prevention strategies. So let’s dive in and uncover the key dissimilarities between these troublesome substances.

Table of Contents

What is Scale?

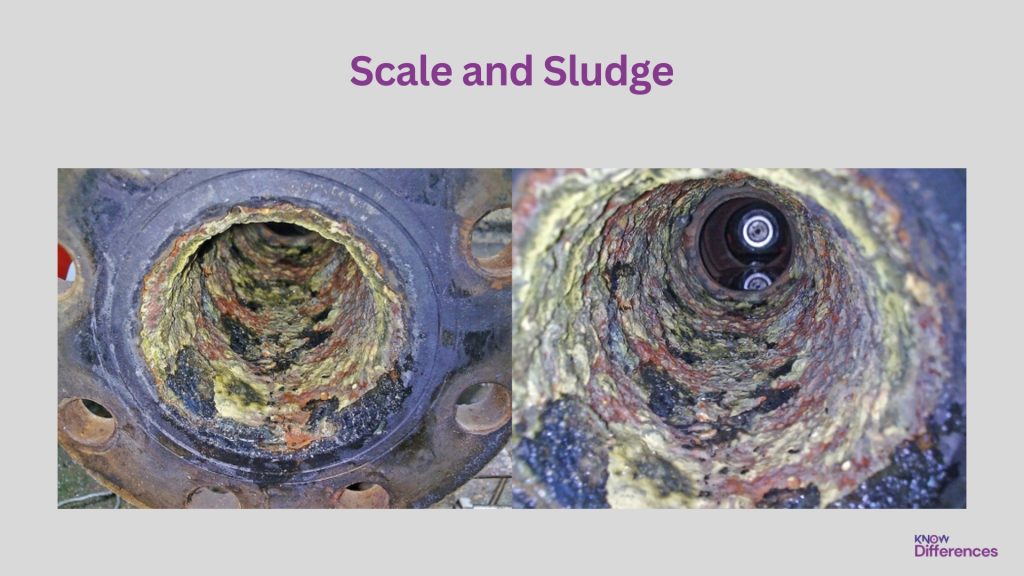

Scale formation occurs when mineral deposits in water accumulate on the surfaces of a boiler. These deposits primarily consist of mineral salts such as calcium carbonate, magnesium silicate, and iron oxide. The high temperatures and pressures within the boiler create favorable conditions for scale formation. If left untreated, scale can impede heat transfer, leading to reduced efficiency and increased energy consumption. To identify scale buildup, one should look for hard, crusty deposits on heat transfer surfaces, which can significantly hinder boiler performance.

What is Sludge?

Unlike scale, which forms from mineral deposits, sludge originates from suspended impurities present in the water. It comprises a combination of organic and inorganic substances, including rust, dirt, oil, and microbial growth. Sludge typically manifests as a soft, gel-like or viscous material that can accumulate in low flow areas and stagnant water conditions. Detecting sludge buildup requires vigilance, as it may not be as visually apparent as scale.

Here’s a comparison table highlighting the possible differences between scale and sludge in boilers:

| Aspect | Scale | Sludge |

|---|---|---|

| Formation | Formed by mineral deposits in the water | Formed by suspended impurities in the water |

| Composition | Mainly composed of mineral salts | Composed of organic and inorganic substances |

| Appearance | Hard, crusty deposits on heat transfer surfaces | Soft, gel-like or viscous material |

| Formation Conditions | High temperature and pressure conditions | Low flow areas and stagnant water conditions |

| Effects on Boiler | Reduces heat transfer efficiency, increases fuel consumption, and may lead to overheating or failure of equipment | Reduces water flow, increases corrosion rates, and can block pipes or valves |

| Removal | Requires mechanical or chemical descaling methods | Often removed through blowdown and regular boiler water treatment |

| Prevention | Water treatment, softening, and regular cleaning/maintenance | Proper water treatment, effective filtration, and regular blowdown |

| Impact on Energy Efficiency | Decreases energy efficiency and increases operating costs | Decreases energy efficiency and increases operating costs |

Effects of Scale on Boiler Performance:

Scale buildup poses several detrimental effects on boiler performance. Firstly, it diminishes heat transfer efficiency by acting as an insulating barrier, preventing effective heat exchange between the combustion gases and the water. Consequently, more fuel is required to generate the desired heat output, leading to increased operational costs. Moreover, scale deposits can cause localized overheating, potentially resulting in the failure of critical boiler components, such as tubes or heat exchangers.

Impact of Sludge on Boiler Operation:

Similar to scale, sludge accumulation can have adverse consequences on boiler operation. One significant effect is reduced water flow, which restricts the amount of heat that can be transferred from the combustion chamber to the water. Additionally, sludge acts as a catalyst for corrosion, accelerating the degradation of boiler components. Over time, sludge deposits can accumulate and obstruct pipes and valves, impeding the proper functioning of the boiler system and potentially leading to severe damage.

Removing Scale and Sludge:

To restore optimal boiler performance, the removal of scale and sludge is crucial. Mechanical descaling methods involve physically removing scale deposits using tools like brushes, scrapers, or high-pressure water jets. Chemical cleaning techniques, on the other hand, utilize specific chemical agents to dissolve and dislodge scale from the surfaces. For sludge removal, regular blowdown procedures, which involve draining a portion of the boiler water, can help purge accumulated sludge and prevent its adverse effects.

Preventing Scale and Sludge Formation:

Prevention is key to combatting scale and sludge formation. Water treatment and conditioning play a pivotal role in preventing scale. Techniques such as water softening, reverse osmosis, and ion exchange can help reduce the mineral content in the feedwater, mitigating scale formation. Effective filtration systems are equally important to remove suspended impurities and prevent sludge buildup. Additionally, implementing regular blowdown procedures ensures the removal of dissolved solids and sediments, minimizing the chances of scale and sludge formation.

Energy Efficiency Considerations:

Both scale and sludge negatively impact boiler energy efficiency. By reducing heat transfer efficiency and increasing fuel consumption, they contribute to higher energy costs. However, with proper maintenance, including regular inspections, cleaning, and adherence to preventive measures, the impact of scale and sludge can be minimized. Proactive measures can significantly enhance energy efficiency and prolong the lifespan of the boiler system.

Conclusion:

In conclusion, understanding the differences between scale and sludge is essential for effective boiler maintenance and optimal performance. Scale forms from mineral deposits and impedes heat transfer, while sludge originates from suspended impurities and restricts water flow. Both substances can lead to increased energy consumption, reduced efficiency, and potential equipment failure. By implementing proper removal techniques and preventive measures, such as regular blowdown and water treatment, the adverse effects of scale and sludge can be mitigated. With careful attention and proactive maintenance, boilers can operate efficiently, ensuring optimal performance and minimizing operational costs.

What is the main Difference Between Scale and Sludge in a Boiler System?

Scale in a boiler system refers to the buildup of mineral deposits, typically calcium and magnesium, on the heat transfer surfaces due to the presence of hard water. On the other hand, sludge refers to the accumulation of sediment, rust, and other impurities in the boiler water, which can settle at the bottom of the system. Scale reduces heat transfer efficiency and can lead to overheating, while sludge can cause corrosion and blockages in the system.

What are the disadvantages of scale and sludge?

The disadvantages of scale and sludge in a boiler system include:

- Reduced Efficiency: Scale and sludge act as insulators, reducing the efficiency of heat transfer. This leads to increased fuel consumption and higher energy costs to achieve the desired temperature or pressure.

- Overheating and Boiler Failure: Scale buildup on heat transfer surfaces impedes the transfer of heat, resulting in localized hotspots. This can lead to overheating of the boiler, increasing the risk of system failure or damage to components.

- Increased Maintenance and Repair Costs: Scale and sludge accumulation requires more frequent maintenance and cleaning of the boiler system. Regular descaling and removal of sludge incur additional costs and downtime.

- Corrosion and System Damage: Sludge contains impurities that promote corrosion of boiler components, such as pipes, valves, and heat exchangers. Corrosion weakens the system, leading to leaks, reduced lifespan of equipment, and potential safety hazards.

- Reduced Lifespan: The presence of scale and sludge accelerates the wear and tear of boiler components. The accumulation of these deposits can result in premature failure, requiring replacement or costly repairs.

- Inefficient Water Circulation: Sludge buildup can obstruct water flow, leading to poor circulation within the boiler system. This further exacerbates heat transfer inefficiency and can cause uneven heating or system malfunctions.

- Increased Risk of Water Treatment Chemicals: Scale and sludge can interact with water treatment chemicals, reducing their effectiveness. This may necessitate higher chemical dosages or the use of more aggressive chemicals, potentially impacting the environment and increasing costs.

To mitigate these disadvantages, regular monitoring, maintenance, and implementing appropriate water treatment measures are crucial for preventing scale and sludge formation in boiler systems.