What is a Suspension?

A suspension refers to a heterogeneous mixture in which solid particles are dispersed in a liquid medium. These particles are usually larger than the molecules in the liquid and tend to settle down over time due to the force of gravity. However, the stability of suspensions can be controlled through various mechanisms, such as flocculation and deflocculation.

Importance of Suspension in Various Industries

Suspensions play a crucial role in numerous industries, including pharmaceuticals, ceramics, paints, and many more. They are used to formulate products with desired properties, such as improved texture, stability, and controlled release. Understanding the differences between flocculated and deflocculated suspensions is vital for optimizing product performance and manufacturing processes.

Overview of Flocculated and Deflocculated Suspensions

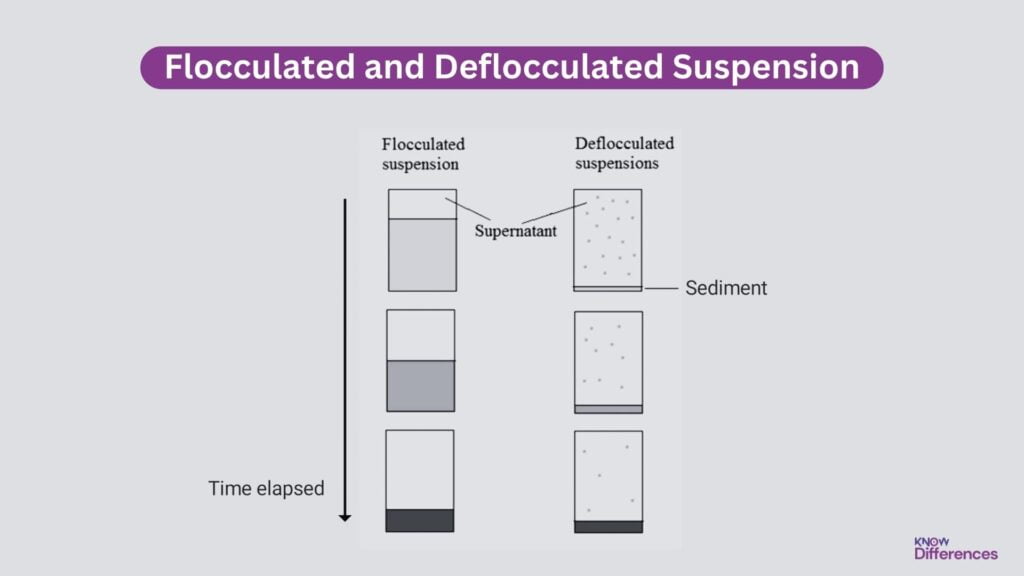

Flocculated and deflocculated suspensions represent two different states of particle dispersion within a liquid medium. Flocculation refers to the aggregation of particles into loose clusters or flocs, while deflocculation involves the dispersion of particles to a uniform, individual state. These states have distinct characteristics, mechanisms, and effects on the properties of suspensions.

Here’s a table highlighting the key differences between flocculated and deflocculated suspensions:

| Differences | Flocculated Suspension | Deflocculated Suspension |

|---|---|---|

| Particle Distribution | Non-uniform particle distribution with particles aggregating into flocs | Uniform particle dispersion without particle aggregation |

| Settling Behavior | Flocs settle quickly due to increased size and weight | Individual particles remain dispersed, preventing settling |

| Rheological Properties | Higher viscosity due to particle size and interactions within flocs | Lower viscosity and better flow properties due to individual particle dispersion |

| Stability and Shelf Life | Limited shelf life due to settling and phase separation | Improved stability and extended shelf life |

| Process Efficiency | Additional processing steps may be required for floc separation | No additional separation steps required, leading to more efficient processes |

| Impact on Product Performance | Advantages in applications requiring rapid settling or controlled aggregation | Benefits in terms of stability, uniformity, and consistency for desired product characteristics and performance |

| Redispersibility | Difficult to redispersed once settled or flocculated | Easily redispersible as individual particles remain dispersed |

| Sedimentation Rate | Higher sedimentation rate due to larger flocs | Lower sedimentation rate due to dispersed particles |

| Particle Interactions | Increased particle interactions within flocs | Reduced particle interactions, leading to lower agglomeration |

| Particle Size Distribution | Broader particle size distribution due to floc formation | Narrower particle size distribution due to individual particle dispersion |

| Sensitivity to Shear | More sensitive to shear forces, leading to further floc formation | Less sensitive to shear forces, maintaining particle dispersion |

| Filtration Efficiency | Reduced filtration efficiency due to larger particle sizes in flocs | Improved filtration efficiency due to smaller and dispersed particles |

| Homogeneity | Less homogeneous due to uneven distribution of flocs | More homogeneous due to uniform particle dispersion |

| Surface Area | Reduced surface area per unit volume due to floc formation | Increased surface area per unit volume due to dispersed particles |

| Optical Clarity | Lower optical clarity due to flocs and light scattering | Higher optical clarity due to dispersed particles |

| Sensitivity to Environmental Factors | More sensitive to changes in pH, temperature, and electrolyte concentration | Less sensitive to environmental factors, maintaining stability |

| Formulation Complexity | Can require additional additives for flocculation control | Simpler formulation as deflocculation is maintained |

Flocculated Suspension

Definition

Flocculated suspension refers to a type of suspension where the solid particles are clustered together into flocs or aggregates. These flocs are formed due to the attractive forces between the particles, such as van der Waals forces or electrostatic interactions.

Characteristics of Flocculated Suspensions

Flocculated suspensions exhibit specific characteristics:

- The flocs in a flocculated suspension are larger in size compared to the individual particles.

- Flocculated suspensions have a higher viscosity and may display thixotropic behavior.

- The sedimentation rate of flocs is relatively slower compared to deflocculated suspensions.

- The flocs can be easily redispersed with gentle agitation.

Mechanism of Flocculation

Flocculation occurs due to the attractive forces between particles, which can be Van der Waals forces, electrostatic interactions, or adsorption forces. When these forces overcome the repulsive forces, the particles come closer and form flocs. Flocculation can be induced by adding flocculating agents or through changes in pH, temperature, or shear forces.

Factors Affecting Flocculation

Several factors influence the flocculation process, including particle concentration, size, and shape, as well as the presence of electrolytes or surfactants. pH and temperature also play a significant role in flocculation, as they can alter the surface charge of particles and affect the balance between attractive and repulsive forces.

Applications of Flocculated Suspensions

Flocculated suspensions find applications in various industries. In wastewater treatment, flocculants are added to facilitate the sedimentation and removal of suspended solids. They are also utilized in the production of ceramics, where controlled flocculation helps in shaping and forming ceramic bodies. Additionally, flocculated suspensions are used in the formulation of certain pharmaceuticals and cosmetics.

Advantages and Disadvantages of Flocculated Suspensions

Here are some advantages and disadvantages of flocculated suspensions:

Advantages:

- Enhanced sedimentation: Flocculated suspensions settle more rapidly due to the larger particle size, leading to improved separation of the solid phase from the liquid phase. This is particularly advantageous in applications such as water treatment and wastewater treatment.

- Increased filterability: The larger flocs in flocculated suspensions can be easily filtered, making the separation process more efficient. This is beneficial in various industries, including pharmaceuticals, where filtration is a crucial step in the production of drugs.

- Improved rheological properties: Flocculated suspensions often exhibit better flow characteristics than deflocculated suspensions. The increased size of the flocs reduces the viscosity and improves the flow behavior, making them easier to handle and process.

- Reduced sensitivity to shear forces: Flocculated suspensions are less susceptible to shear-induced particle rearrangement compared to deflocculated suspensions. This property is advantageous in applications where the suspension undergoes shear forces during handling, transportation, or processing.

Disadvantages:

- Reduced stability: Flocculated suspensions are inherently less stable than deflocculated suspensions. Over time, the flocs may break apart, leading to the reformation of smaller particles and eventual settling or sedimentation. This instability can pose challenges in maintaining the desired suspension properties.

- Irreversible aggregation: The flocculation process in suspensions is often irreversible, meaning that once the particles have aggregated, it can be challenging to disperse them back into individual particles. This limits the reusability and re-dispersion capabilities of flocculated systems.

- Variability in floc size: Flocculated suspensions can exhibit a wide range of floc sizes, leading to heterogeneity in the system. This can affect the performance and consistency of the suspension in certain applications where uniformity is crucial.

- Increased difficulty in formulation: Formulating stable flocculated suspensions requires careful control of various parameters such as pH, concentration, and flocculant dosage. Achieving the desired floc size and stability can be challenging, particularly when dealing with complex systems or a wide range of particle types.

Deflocculated Suspension

Definition

Deflocculated suspension, also known as a dispersed suspension, is a type of suspension where the solid particles are uniformly dispersed and do not form flocs or aggregates.

Characteristics of Deflocculated Suspensions

Deflocculated suspensions exhibit specific characteristics:

- The particles in a deflocculated suspension remain separate and do not aggregate into flocs.

- Deflocculated suspensions have a lower viscosity compared to flocculated suspensions.

- These suspensions tend to have a higher sedimentation rate due to the absence of flocs.

- Deflocculated suspensions may require more energy for redispersion.

Mechanism of Deflocculation

Deflocculation is achieved by introducing substances called deflocculants, which disperse the particles and maintain their separation. These deflocculants work by creating electrostatic or steric repulsion forces between the particles, preventing them from aggregating. The use of suitable dispersants or surfactants can aid in achieving and maintaining deflocculated states.

Factors Affecting Deflocculation

Several factors impact the deflocculation process, including the type and concentration of deflocculants used, pH, ionic strength, and temperature. The selection of appropriate dispersants or surfactants is critical to maintaining particle separation and preventing flocculation. The particle size and surface charge also play a significant role in achieving and sustaining deflocculation.

Applications of Deflocculated Suspensions

Deflocculated suspensions find extensive applications in industries where stability, uniformity, and prolonged shelf life are desired. They are commonly used in the formulation of pharmaceuticals, where maintaining consistent particle dispersion is crucial for dosage accuracy. Deflocculated suspensions are also utilized in the manufacturing of paints, coatings, and inks to achieve desired flow properties and prevent settling.

Advantages and Disadvantages of Deflocculated Suspensions

Here are some advantages and disadvantages of deflocculated suspensions:

Advantages:

- Enhanced stability: Deflocculated suspensions are generally more stable than flocculated suspensions. The individual dispersion of particles prevents them from aggregating or settling, leading to improved suspension stability over time. This is beneficial in applications where long-term stability is crucial, such as in pharmaceutical formulations.

- Homogeneous particle distribution: Deflocculated suspensions exhibit a uniform distribution of particles throughout the suspension. This ensures consistent properties and performance, which is particularly advantageous in applications where uniformity is critical, such as coatings or pigments.

- Improved rheological control: Deflocculated suspensions offer better control over the rheological properties, such as viscosity and flow behavior. The individual particle dispersion allows for precise adjustment of these properties, making deflocculated systems suitable for applications where specific flow characteristics are desired.

- Ease of re-dispersion: Deflocculated suspensions can be easily re-dispersed if they undergo settling or sedimentation. Unlike flocculated suspensions, the individual particles can be readily dispersed back into a stable suspension with the appropriate mixing or agitation, allowing for easy recovery and reusability.

Disadvantages:

- Increased viscosity: Deflocculated suspensions tend to have higher viscosities compared to flocculated suspensions with the same solid content. The lack of particle aggregation leads to increased interparticle interactions, resulting in higher resistance to flow. This can pose challenges in certain applications where low viscosity is desired, such as in some coatings or ink formulations.

- Hindered sedimentation or filtration: Due to the individual particle dispersion, deflocculated suspensions may exhibit slower sedimentation rates or reduced filterability. The small particle size and lack of floc formation make the separation of the solid phase from the liquid phase more difficult, requiring additional time or more advanced separation techniques.

- Shear sensitivity: Deflocculated suspensions can be more susceptible to shear-induced particle rearrangement and particle-particle interactions. When exposed to shear forces, such as during mixing or processing, the particles may reaggregate, leading to changes in suspension properties or instability.

- Higher formulation complexity: Formulating stable deflocculated suspensions requires careful control of various factors, such as the selection and concentration of dispersants or stabilizers. Achieving the desired stability and rheological properties can be more challenging and may require more sophisticated formulation strategies.

Difference between Flocculated and Deflocculated Suspensions

Particle Distribution and Settling Behavior

The primary difference between flocculated and deflocculated suspensions lies in the particle distribution and settling behavior. Flocculated suspensions exhibit non-uniform particle distribution, with particles aggregating into flocs that settle quickly. On the other hand, deflocculated suspensions maintain a uniform particle dispersion, preventing settling and sedimentation.

Rheological Properties

Flocculated suspensions often display higher viscosities due to the increased particle size and interactions within the flocs. In contrast, deflocculated suspensions generally exhibit lower viscosities and better flow properties due to the individual particle dispersion. This difference in rheological behavior has implications for processing, handling, and application of the suspensions.

Stability and Shelf Life

Flocculated suspensions have a limited shelf life due to their tendency to settle and undergo phase separation over time. The flocs can readily settle under the influence of gravity, leading to reduced stability. In contrast, deflocculated suspensions offer improved stability and extended shelf life as individual particles remain dispersed, minimizing sedimentation and phase separation.

Impact on Process Efficiency

Flocculated suspensions may require additional processing steps, such as filtration or centrifugation, to separate the flocs from the liquid phase. This can increase the complexity and cost of the manufacturing process. In contrast, deflocculated suspensions can be readily used without the need for additional separation steps, leading to more efficient and streamlined production processes.

Effect on Product Performance

The choice between flocculated and deflocculated suspensions can significantly impact product performance. Flocculated suspensions may offer advantages in certain applications where rapid settling or controlled aggregation is desired. Deflocculated suspensions, on the other hand, provide benefits in terms of stability, uniformity, and consistency, which are critical for achieving desired product characteristics and performance.

Conclusion

In summary, understanding the difference between flocculated and deflocculated suspensions is essential for optimizing product performance and manufacturing processes. Flocculated suspensions involve the aggregation of particles into flocs, while deflocculated suspensions maintain individual particle dispersion. These states have distinct characteristics, mechanisms, and effects on suspension properties, such as particle distribution, settling behavior, stability, and rheological properties. By selecting the appropriate suspension state, industries can achieve desired product attributes and improve process efficiency.