When it comes to marine propulsion systems, two terms that often pop up in discussions are “impeller” and “propeller.” These essential components play a crucial role in moving watercraft efficiently through water, but they are distinct in design and function. In this article, we will delve into the differences between impellers and propellers, exploring their respective features, applications, and advantages.

Table of Contents

Impeller vs. Propeller: Quick Overview

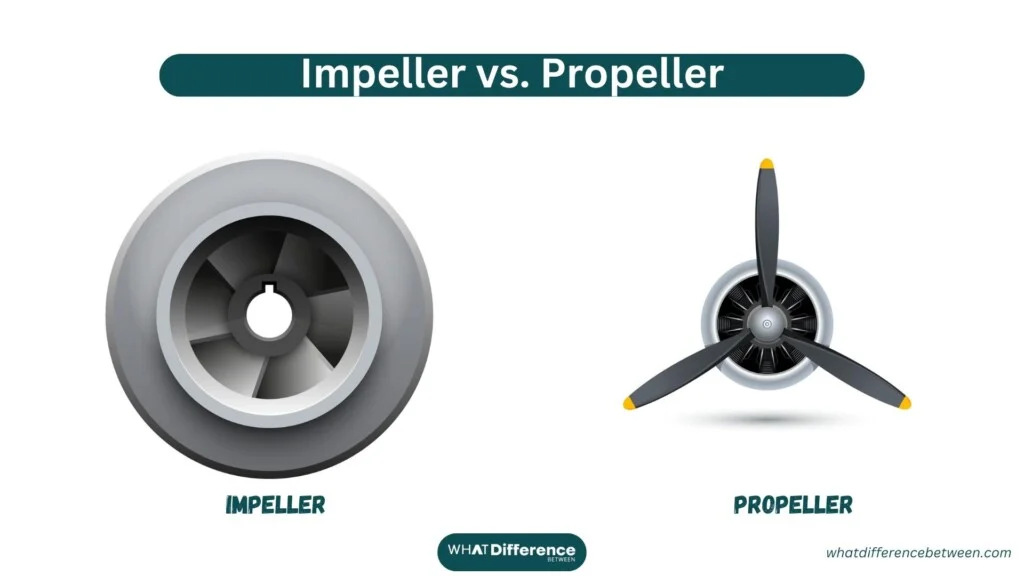

The main difference between an impeller and a propeller is their function. An impeller is a rotor that is used to increase the flow and pressure of a fluid by producing a sucking force. A propeller is a fan-shaped device that drives out or propels a fluid by pushing against it.

In other words, an impeller is used to move fluids, while a propeller is used to propel objects through fluids.

Here’s a table highlighting the key differences between impellers and propellers:

| Aspect | Impellers | Propellers |

|---|---|---|

| Function | Used in pumps to move liquids or gases | Used in aircraft and watercraft to provide thrust |

| Shape | Typically have curved blades | Typically have straight or slightly curved blades |

| Medium | Move fluids (liquids or gases) | Move through air or water |

| Application | Used in industrial processes | Used in aviation, marine, and automotive industries |

| Mounting | Can be submerged or in open air | Mounted externally on aircraft or watercraft |

| Orientation | Often horizontal | Often horizontal or vertical |

| Efficiency | Designed for efficient fluid movement | Designed for efficient propulsion |

| Blade Design | Blades may have various shapes and angles | Blades are aerodynamically optimized |

| Speed | Operate at lower speeds | Operate at higher speeds |

| Thrust Direction | Generate radial flow | Generate axial flow |

| Power Source | Typically driven by electric motors | Driven by engines (jet, piston, etc.) |

| Control | Alters fluid flow in systems | Controls direction and speed of movement |

| Examples | Mixing tanks, chemical processing | Airplanes, helicopters, boats, submarines |

What is an Impeller?

An impeller is a specialized rotating component found within pumps and jet propulsion systems. Unlike propellers, which have a series of blades attached to a central hub, an impeller typically consists of multiple curved blades or vanes arranged around a central shaft. This design allows impellers to draw in fluids and create a high-velocity flow, making them well-suited for applications requiring high pressure or the movement of liquids with solid particles.

The impeller is typically made of metal, such as steel or bronze. However, it can also be made of plastic or other materials. The material of the impeller is chosen based on the application and the properties of the fluid being pumped.

Here are some of the common types of impellers:

- Centrifugal impeller: This is the most common type of impeller. It is used in centrifugal pumps, which are used to move fluids from one place to another.

- Axial impeller: This type of impeller is used in axial pumps, which are used to move fluids in a straight line.

- Mixed flow impeller: This type of impeller is a combination of centrifugal and axial impellers. It is used in pumps that need to move fluids both radially and axially.

Applications of Impeller

Impellers find their niche in various industries, from chemical processing to water treatment, and especially in watercraft propulsion systems. In marine applications, impellers are commonly used in jet drives, which are often favored for their agility, shallow-water operation, and minimal risk of damage from submerged objects. Jet boats and personal watercraft rely on impellers to provide powerful acceleration and maneuverability, making them popular choices for recreational and rescue purposes.

Advantages of Impellers

- Agility: Impeller-driven watercraft are known for their agility and responsiveness. The absence of a protruding propeller allows for better maneuverability, essential for navigating tight spaces or rapidly changing conditions.

- Shallow-Water Operation: Impellers can operate in shallow waters without the risk of striking the seabed, which is advantageous for exploring shallower coastal areas.

- Reduced Risk of Damage: The enclosed design of impellers minimizes the chances of damage from floating debris or underwater obstacles.

What is a Propeller?

A propeller is a rotating device with blades that are shaped to generate thrust by pushing water in a specific direction. The central hub of a propeller connects the blades, and the design can vary from a few blades to several, each affecting the performance and efficiency of the propeller.

Applications of Propeller

Propellers are the dominant choice for propulsion in a wide range of waterborne vessels, from small pleasure boats to massive cargo ships. They are well-suited for applications that require sustained speed and efficiency over longer distances. Sailboats often employ propellers for auxiliary power, and they are also commonly found in conventional outboard and inboard motor setups.

Advantages of Propellers

- Efficiency: Propellers are known for their high efficiency and ability to provide continuous thrust over extended periods. This makes them ideal for long voyages or steady cruising.

- Diverse Applications: From leisure boating to industrial shipping, propellers are versatile and can be tailored to meet specific vessel requirements.

- Fuel Economy: Due to their efficient thrust generation, propellers often result in better fuel economy compared to some impeller-driven systems.

Main Differences Between Impellers and Propellers

Design and Construction

Impellers are typically designed with multiple curved blades or vanes attached to a central shaft. These blades create a high-velocity flow by drawing in fluids and pushing them outwards. The enclosed design of impellers makes them well-suited for applications involving liquids with solid particles, such as wastewater treatment or jet propulsion systems in watercraft.

Propellers consist of blades that are shaped to generate thrust by pushing water in a specific direction. They are connected to a central hub, and the number of blades can vary. The design of propellers is optimized for efficiency and sustained thrust, making them a common choice for various waterborne vessels, from pleasure boats to large cargo ships.

Fluid Movement:

Impellers generate fluid movement primarily through centrifugal force. The rotating impeller creates a low-pressure region at its center, causing fluid to be drawn in from the surrounding area and then pushed outward radially with increased velocity.

Propellers generate fluid movement through a combination of thrust and drag. As the blades rotate, they push the fluid in the direction opposite to their rotational movement, creating a propulsive force that propels the vehicle forward or backward.

Maneuverability and Agility

Impellers are prized for their agility and maneuverability. The absence of a protruding propeller allows watercraft equipped with impellers to navigate tight spaces and make quick turns, making them suitable for recreational activities and operations in confined areas.

While propellers offer efficient thrust and steady performance, their maneuverability might not match that of impellers. They are better suited for vessels that prioritize straight-line cruising and stable operation over rapid changes in direction.

Shallow-Water Operation

Impellers excel in shallow-water environments. Their design allows watercraft to operate in waters where traditional propellers might risk striking the seabed. This is particularly advantageous for exploring coastal areas with varying water depths.

Traditional propellers have limitations when it comes to operating in shallow waters. Their deeper positioning can make them vulnerable to damage from underwater obstacles and uneven terrain.

Risk of Damage

Impellers have a reduced risk of damage from floating debris or underwater obstacles due to their enclosed design. This makes them a preferred choice in scenarios where water conditions might include debris or potential hazards.

Traditional propellers, due to their exposed blade design, are more susceptible to damage from debris and obstacles in the water. This vulnerability can impact vessel operation and lead to costly repairs.

Choosing the Right System: Factors to Consider

Vessel Type and Purpose

Selecting between an impeller and a propeller involves considering the vessel’s type and intended use. For smaller watercraft requiring agility and maneuverability, such as personal watercraft or rescue boats, impellers could be the preferred choice. On the other hand, vessels that prioritize fuel efficiency and steady performance, like cargo ships or pleasure cruisers, are likely to opt for propeller systems.

Water Conditions

The conditions in which a watercraft will operate play a vital role in system selection. Impellers are well-suited for calmer waters and areas with potential debris, as their enclosed design reduces the risk of damage. Propellers, with their efficient and consistent thrust, excel in open waters and scenarios where sustained speed is essential.

Maintenance and Repairs

Maintenance considerations can also influence the decision-making process. Impellers might require more frequent inspection and cleaning due to their susceptibility to clogs, while propellers generally have a straightforward maintenance routine involving occasional cleaning and checks for damage.

Conclusion

In the world of marine propulsion, the choice between an impeller and a propeller hinges on numerous factors. Impellers shine in agility and shallow-water maneuverability, making them favorites for certain recreational and operational applications. Propellers, time-tested and efficient, dominate in scenarios demanding continuous thrust and higher fuel economy. Understanding the nuances and advantages of these propulsion systems is crucial for optimizing vessel performance and achieving the desired outcomes on the water. Whether it’s the nimble impeller or the steadfast propeller, each has a unique role to play in keeping the maritime world moving forward.